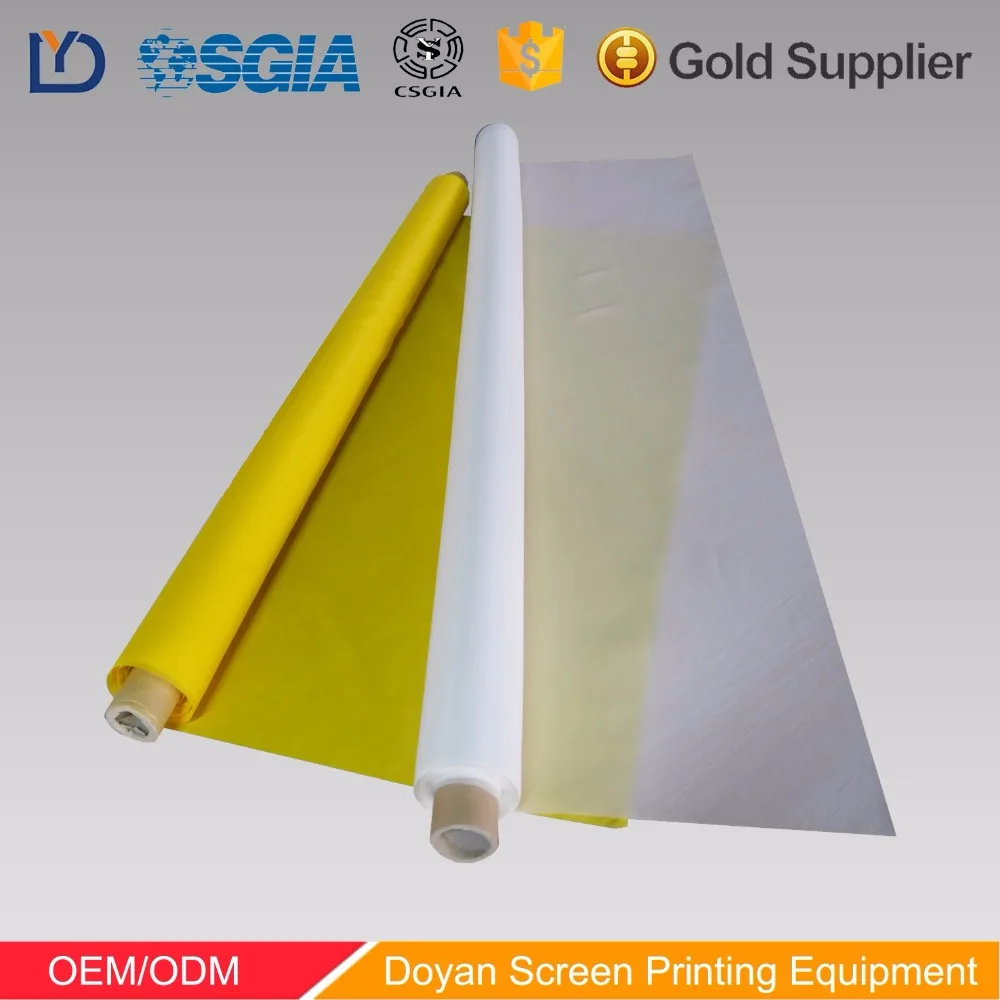

Screen printing polyester mesh

Width: 165cm

Length: 50m

Application: Screen printing

Price: USD 12.00/meter

Material:100% polyester

Mesh count:10T-165T(25-420mesh)

Width:0.6M-3.9M

Mesh diameter:31-250um

Weave Type:plain

Mesh color:White/yellow

Monofilament Style:yes

Mesh width:105-360cm

Application:Screen printing

Stretch tension:0-30N

Screen printing polyester mesh

| Name:Screen printing mesh |

|

|

|

Material:100% polyester |

Mesh count:10T-165T(25-420mesh) |

|

|

Width:0.6M-3.9M |

Mesh diameter:31-250um |

|

|

Weave Type:plain |

Mesh color:White/yellow |

|

|

Monofilament Style:yes |

Mesh width:105-360cm |

|

|

Application:Screen printing |

Stretch tension:0-30N |

|

|

· •Made from high modulus, low elongation monofilament polyester. |

||

|

· •Ideal for printing on t-shirts, textiles and ceramic. |

||

|

• No surface treatment.

|

||

|

Best Mesh For The Job: |

|

|

• 4 and 38 mesh is used mainly for glitter inks that need a very open mesh for printing. |

|

|

• 60 mesh is often used for printing smaller glitter and most shimmer inks. |

|

|

• 86 mesh is also used for printing shimmer inks and for laying down thick layers of ink for high-density printing. It also works well for printing foil adhesive. |

|

|

• 110 mesh makes printing white and other thick inks easy. It is ideal for spot color printing since it holds less detail than 156 mesh and lays down a thick layer of ink for maximum coverage. |

|

|

• 125 mesh is one of the most commonly mesh sizes in screen printing. It works great for printing white ink and other colored inks that have a thicker viscosity. |

|

|

• 156 mesh is great for general purpose textile printing with basic to semi-fine detail. It will hold a little finer detail than a 110 mesh while also working well with thinner inks. |

|

|

• 200 mesh is great for printing more detailed prints that need a thinner layer of ink than a 156 mesh. It works very well with thinner inks and is a good middle-range mesh size. |

|

|

• 230 mesh is great for high-end fine detail printing. A 230 mesh can hold halftones very well and also lets a little more ink through then a 305 mesh. The yellow color prevents light from reflecting through the threads of the mesh and keeps a sharper image when burning. |

|

|

• 280 mesh screens are great for high-end fine detail printing. A 280 mesh can hold halftones very well and also lets a little more ink through then a 305 mesh. |

|

|

•305 mesh holds extremely high detail, letting through only a thin layer of ink. This allows for a very soft hand on the garment and is great for use in printing halftones and process prints. The yellow color prevents light from reflecting through the threads of the mesh and keeps a sharper image when burning. |

|

|

White or Yellow mesh? |

|

|

White mesh is the more economical of the two, and is primarily seen in lower mesh counts used for less-detailed designs. Higher count mesh is usually dyed yellow because the color yellow acts as a canceling factor for UV light and prevents refraction along the mesh strands when burning your screens. This allows for a more focused and precise exposure, keeping your screens as crisp as possible. |

|

|

|

Hebei Doyan Screen Printing Equipment Co.,Ltd is a professional export polyester screen printing mesh and aluminum frame manufacturer and exporter of screen printing materials and equipment.Our product engineers work closely with customers in many diverse industries to develop product solutions that are tailored to their individual project specifications.Currently sold into over 50 countries worldwide. Enterprise faith: faithfulness,Mutual Benefit Enterprise purpose:provide high quality products and excellent service. |

| Handle squeegee |

Mesh |

Squeegee |

Aluminum frame |

Send your inquiry details in the below for Free Sample, just click "Send"! Thank you!

*Your email address will not be published. Required fields are marked.